Finding better ways to provide the materials the world needs

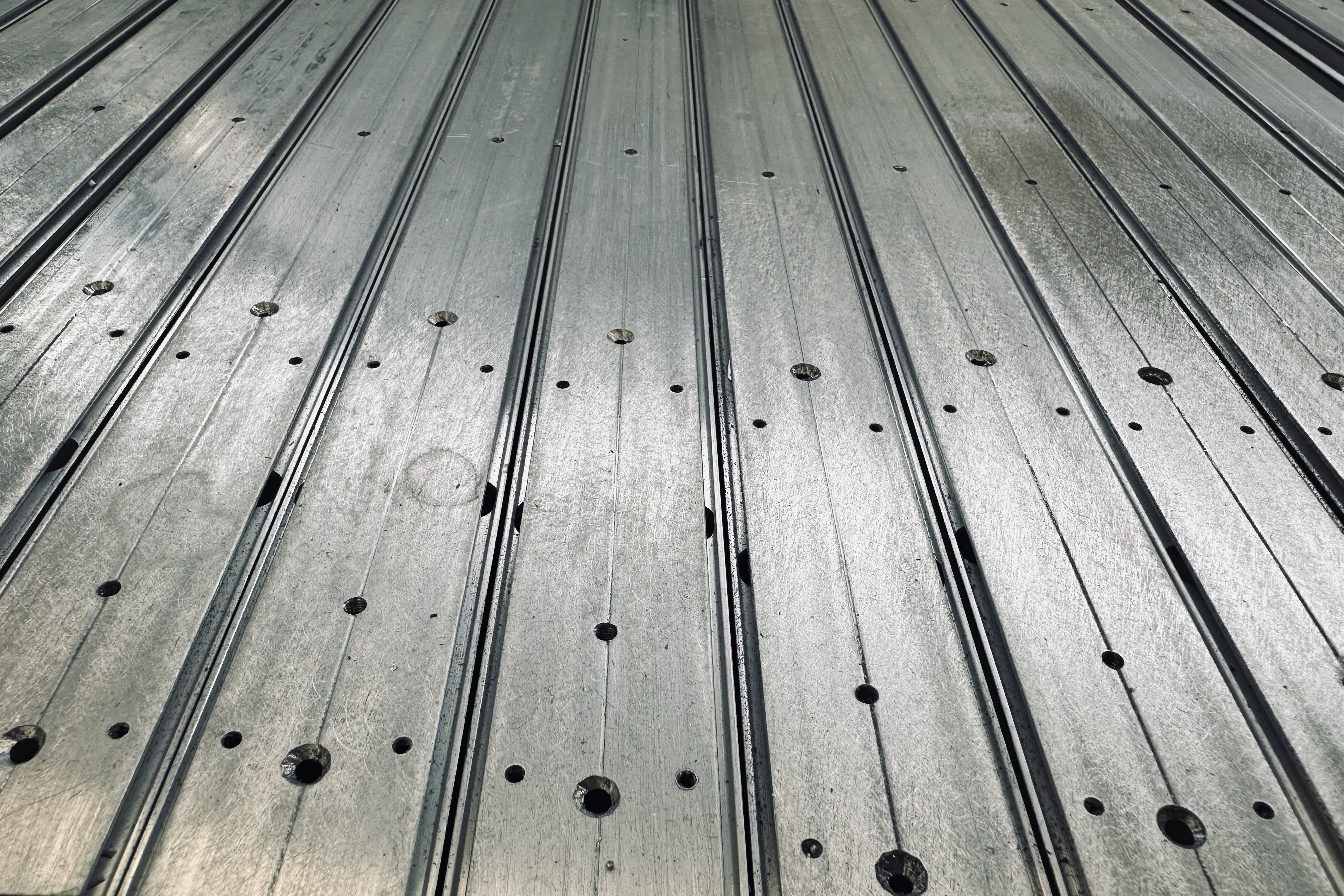

The drive for innovation and continuous improvement is at the heart of our purpose Extruded Aluminum Steps

Climate change is at the heart of our business strategy

Finding better ways to do things is in our DNA

We supply the metals and minerals used to help the world grow and decarbonise

Iron ore is the primary raw material used to make steel

7 things the world will need for a low-carbon future

Wind, sun and water – what else do you need to make renewable energy work?

Sustainability – the expectation, not the exception

Shaping our aluminium product offering to meet demand for greener metals

Bringing to market materials critical to urbanisation and the transition to a low-carbon economy

Look inside a mine of the future

Our most intelligent mine yet is pioneering new mining technologies

A long-life, low-cost and low-carbon lithium source

The world’s largest untapped high-grade iron ore deposit

Providing materials the world needs in a responsible way

We have a responsibility to extract the full value from the minerals and materials we produce in the safest and most sustainable way possible

We’re targeting net zero emissions by 2050

We’ve launched a new interactive map of our tailings facilities

We aim to deliver superior returns to our shareholders while safeguarding the environment and meeting our obligations to wider society

Annual results 2023: released Wednesday 21 February ~ 5:30 (GMT) / 16:30 (AEDT)

Get the latest news, stories and updates

A new way to decarbonise steel

Renewing bauxite residue while reducing our environmental impact

Statement - Update on Fort Smith plane crash, Northwest Territories, Canada

Discover more about life at Rio Tinto

If you want to drive real change, we have just the place to do it

Supporting new parents of any gender with equal access to parental leave

Lightweight and infinitely recyclable, aluminium is found in everything from jet engines to electric vehicles to mobile phones. It is the most abundant metal in the Earth’s crust, and one of the world’s fastest growing major metals.

But we are only scratching the surface of the opportunities for aluminium to be a part of our everyday lives. For example, analysts predict the use of aluminium in lightweight cars and trucks in North America will increase by about 30% – from 177 kilograms per vehicle in 2015 to 227 kilograms in 2025. According to the Aluminium Stewardship Initiative (ASI), for every 10% reduction in the weight of a vehicle, fuel economy increases by about 7%. Over its lifetime, every kilogram of aluminium that replaces heavier materials in a car or light truck can save a net 20 kilograms of carbon dioxide emissions. Aluminium is made from bauxite, or aluminium ore. Bauxite is the basic raw material that is refined into alumina, which in turn is sent to smelters for processing into aluminium.

First discovered near Les Beaux in the South of France in 1821, bauxite was initially called “beauxite”. In 1886, Charles Martin Hall and Paul Héroult independently developed a process for making aluminium from alumina. And in 1887, Austrian scientist Karl Josef Bayer patented his self-titled process for extracting alumina from bauxite. Today, the Bayer process and the Hall-Héroult process are still combined to process bauxite ore into alumina, and then convert it into aluminium.

We are a global leader in aluminium, with a large-scale, vertically-integrated business: bauxite mines and alumina refineries as well as smelters producing aluminium certified as responsible, to now being able to offer fully recycled aluminium products through our Matalco joint venture. Managing the process from start to finish allows us to bring quality products to our customers reliably and efficiently: from high-grade bauxite for the global seaborne trade to sustainably sourced aluminium for beverage packaging to new, lighter alloys for the automotive industry. Our Canadian operations average in the first decile of the industry cost-curve and produce aluminium using clean, renewable hydropower.

We produce some of the highest quality, lowest-carbon footprint aluminium in the world: the greenhouse gas emissions intensity of our managed Atlantic Operations smelters represents less than one-fifth of the industry average. Through ELYSIS, our joint venture with Alcoa, supported by Apple and the governments of Canada and Quebec, we are helping to further develop a breakthrough smelting technology to produce aluminium with no direct greenhouse gas emissions, which is now being used in Apple products.

In 2018, we became the first company to receive certification from the ASI as producing “responsible” aluminium in Canada. Our diverse alloys are designed to meet customer needs. In 2019, we launched Revolution-Al™, a new aluminium alloy developed to make lighter car wheels, which can help to make cars safer and more appealing to end consumers with reduced CO2 emissions.

We are also reducing the volume of waste we produce and creating new value for our business, such as supplying anhydrite, a by-product from our Vaudreuil alumina refinery in Canada, to be a fertiliser to our neighbouring blueberry growers.

Rio Tinto becomes official aluminium partner of the Montreal Canadiens

Sites certified as responsible by Aluminium Stewardship Initiative

Bauxite mines in Australia, Brazil and Guinea

Facilities in the US* and Canada* producing recycled aluminium

We all want to know more about the products we buy – where they come from and how they are made. So to help our customers meet this demand from consumers, we created START – the first digital sustainability label for the aluminium industry.

Using blockchain technology, START works like a ‘nutrition label’ for several of our products including aluminium – providing transparency and traceability across our supply chain, so end users can see environmental, social and governance information across 10 areas including carbon footprint, water use and recycled content.

And by showing how our aluminium is made – from mine to market – we are empowering our customers and theirs to make a more sustainable choice.

We are now offering Aluminium Stewardship Initiative (ASI) certified aluminium from all of our Canadian operations, through a ‘chain of custody’ spanning Rio Tinto’s Gove bauxite mine in Australia to its alumina refinery, aluminium smelters and casthouses in Quebec and British Columbia, Canada.

The ASI aims to create sustainability and transparency throughout the aluminium industry. It has developed the world’s first global Responsible Aluminium Standard, used to assess environmental, social and governance practices across the aluminium supply chain for responsible sourcing. This is the highest internationally recognised standard for robust environmental, social and governance practices across the life cycle of aluminium production, use and recycling.

This certification gives our customers independent assurance that the metal they use to make aeroplane parts, cars, smartphones and other products has been made to standards that promote the protection of biodiversity, respect for Indigenous peoples’ rights, water management and low-carbon emissions. ASI also creates a traceability mechanism – the first of its kind for any industrial metal – so that companies like AB InBev can be sure that the aluminium they buy has been manufactured to meet ASI standards at every stage of the process.

The use of Aluminium Stewardship Initiative (ASI) Certified Aluminium is an important milestone towards reducing the impact that the world’s second most used base metal has on the planet.

In 2018, we launched ELYSIS, a partnership with Alcoa, supported by Apple and the governments of Canada and Québec. ELYSIS is further developing breakthrough technology that eliminates direct greenhouse gas emissions from the aluminium smelting process, replacing them with pure, clean oxygen. In Canada alone, if this technology were to be used at every smelter in the country, it could eliminate the equivalent of 6.5 million metric tonnes of greenhouse gas emissions – roughly equivalent to taking nearly 1.8 million cars off the road.

ELYSIS will work towards bringing this technology to the market at its Research and Development Centre, located within Rio Tinto’s Complexe Jonquière. ELYSIS has selected our Alma smelter in Saguenay-Lac-Saint-Jean, Quebec, for the first installation and demonstration of its inert anode technology at a commercial size of 450 kiloamperes (kA).

In November 2021, ELYSIS successfully produced aluminium without any direct greenhouse gas emissions at its Research and Development Centre using a full industrial design at a size comparable to small smelting cells operating in the industry today.

In March 2022, Apple announced that they would purchase a first batch of commercial-purity aluminium produced at the Research and Development Centre to manufacture their new iPhone SE.

And in a step towards putting a fully traceable beverage can in the hands of consumers, in June 2022 we partnered with Corona Canada to launch of Canada’s first specially-marked, low carbon beverage can, manufactured by Ball Corporation. The cans, now available through a pilot in Ontario, use Rio Tinto aluminium and leverage ELYSISTM technology. As part of this limited release, the 1.2 million cans produced have a QR code printed on them to inspire consumers to learn more about the cans’ low carbon footprint.

Work is now focused on scaling up ELYSISTM technology for even larger commercial-size cells, which should become operational in 2023. Construction of these prototype cells is now well underway at the end of an existing potline at Rio Tinto’s Alma smelter.

At nearly the northernmost edge of the Northern Territory sits the first mine in Australia to be 100% owned and operated, across the supply chain, by Traditional Owners – the Gumatj, one of the Yolngu clans in the area.

Located at Gulkula, in Northeast Arnhem Land, the mine provides employment opportunities for Traditional Owners. Among these are new graduates from the Gulkula Mine Training Centre, partly funded with A$2.4 million from Rio Tinto, that gives on-the-job training and support to the Yolngu people to help them build mining careers in the Northern Territory and beyond.

We have worked closely with Traditional Owners from the start, and we are committed to the success of this mine – both as a customer and a partner.

We buy bauxite from the mine to sell to international customers, and celebrated the mine’s first bauxite shipment in 2018.

By tracing the steps from START to finish

Using blockchain to help trace our responsible materials

A new pilot program will help us find out

While aluminium is essential for low-carbon solutions, including lightweight cars and energy efficient buildings, it takes a lot of energy to produce.

As Queensland’s largest energy user, we have an important role to play in driving the development of renewable energy sources to power our Queensland-based Aluminium operations and supporting the state’s renewable energy targets.

We have called for proposals to develop large-scale wind, solar and firming energy generating systems that can progressively start supplying power to the Boyne smelter (BSL), the Yarwun alumina refinery and the Queensland Alumina refinery (QAL). We expect this future wind and solar generated energy will help underpin Central Queensland’s transformation into a sustainable green industrial hub.

Transitioning Queensland’s energy source on this scale is a multi-year and multi-stakeholder undertaking and is an outcome of the Statement of Cooperation we signed with the Queensland Government in October 2021 to work towards establishing more renewable energy in Central Queensland.

The three Gladstone Aluminium operations require 1,140MW of reliable power, consisting of 960MW for BSL and 180MW for Yarwun and QAL. 1GW of reliable power is equal to about 4GW of wind and solar in a good location with firming, so we are seeking proposals for more than 4GW, as not all proposals will come to fruition.

This is a Request For Proposals (RFP) process only at this stage – we have not committed capital. Any investment in Queensland renewable projects will be in line with our capital allocation programme and subject to our rigorous investment review processes.

We anticipate that the RFP will flush out many projects at various stages of development and with different funding options. For example, some projects may be developed and owned by third parties, and sell us the power, while we may take a greater role in development of others.

We are considering all options, from building and developing ourselves to just taking the power supply. All projects will need to be developed in line with our environmental, social and governance standards – including working closely with local communities – and relevant state and federal laws.

We want to secure assets that can be developed in stages. We would hope to have some projects delivering power to the market by 2025 but expect the majority to be built and commissioned by 2030.

Finding better ways to provide the materials the world needs

How we process personal data provided or obtained through this website.

With the exception of the use of cookies, Rio Tinto generally does not seek to collect personal data through this website. However if you choose to provide personal data to Rio Tinto through this website (for example, by sending us an email), we will process that personal data to answer your query and if relevant, to manage our business relationship with you or your company. We won't process that personal data for other purposes except where required to meet our legal obligations or otherwise as authorised by law and notified to you.

If you choose to subscribe to our media releases or other communications, you can unsubscribe at any time (by following the instructions in the email or by contacting us).

With your consent, our website uses cookies to distinguish you from other users of our website. This helps us to provide you with a good experience when you browse our website and also allows us to improve our site. A cookie is a small file of letters and numbers that we store on your browser or the hard drive of your computer if you agree. Cookies contain information that is transferred to your computer's hard drive.

As some data privacy laws regulate IP addresses and other information collected through the use of cookies as personal data, Rio Tinto’s processing of such personal data needs to comply with its Data Privacy Standard (see Part 1 of our Privacy Policy), and also applicable data privacy laws.

With the exception of the use of cookies (explained below), Rio Tinto generally does not seek to collect personal data through this website. However if you choose to provide personal data to Rio Tinto through this website (for example, by sending us an email), we will process that personal data to answer your query and if relevant, to manage our business relationship with you or your company. We won't process that personal data for other purposes except where required to meet our legal obligations or otherwise as authorised by law and notified to you.

Part 1 of this Privacy Policy contains the Rio Tinto Data Privacy Standard, which provides an overview of Rio Tinto’s approach to personal data processing. There is additional information in the appendices to the Data Privacy Standard, including information about disclosures, trans-border data transfers, the exercise of data subject rights and how to make complaints or obtain further information relating to Rio Tinto’s processing of your personal data.

If you choose to subscribe to our media releases or other communications, you can unsubscribe at any time (by following the instructions in the email or by contacting us at digital.comms@riotinto.com).

With your consent, our website uses cookies to distinguish you from other users of our website. This helps us to provide you with a good experience when you browse our website and also allows us to improve our site.

A cookie is a small file of letters and numbers that we store on your browser or the hard drive of your computer if you agree. Cookies contain information that is transferred to your computer's hard drive.

As some data privacy laws regulate IP addresses and other information collected through the use of cookies as personal data, Rio Tinto’s processing of such personal data needs to comply with its Data Privacy Standard (see Part 1 of this Privacy Policy), and also applicable data privacy laws.

These Cookies are used to provide a better user experience on the site, such as by measuring interactions with particular content or remembering your settings such as language or video playback preferences.

These Cookies allow us to analyse site usage in order to evaluate and improve its performance. They help us know how often you come to our site and when, how long you stay and any performance issues you experience whilst you are on our site.

Machinery And Equipment Aluminum These Cookies are used by advertising companies to inform and serve personalised ads to your devices based on your interests. These Cookies also facilitate sharing information with social networks or recording your interactions with particular ads.